Introduction – Why 2026 Is a Turning Point for Supply Chains

Over the past few years, one lesson has become very clear: supply chains rarely fail because of one major issue. Instead, they break down due to many small coordination mistakes that pile up over time. As we approach 2026, logistics coordination is no longer a “nice to have.” In fact, it has become the backbone of supply chain survival.

To put it simply, think of your supply chain like an orchestra. Even with the best musicians, poor coordination only creates noise. In the same way, companies that master logistics coordination will move faster, reduce costs, and recover more quickly from disruptions. Meanwhile, those that ignore it will struggle to keep pace.

So, let’s explore the most practical and real-world logistics coordination hacks that can truly protect your supply chain in 2026.

Understanding Logistics Coordination in the Modern Era

What Is Logistics Coordination?

Logistics coordination refers to aligning people, processes, data, and technology across the entire supply chain. In other words, it ensures that suppliers, warehouses, carriers, and customers all move in the same direction at the right time.

However, coordination goes far beyond simply moving goods. More importantly, it focuses on synchronizing decisions so that every action supports the bigger picture.

Why Poor Coordination Breaks Supply Chains

When coordination is weak, problems appear quickly. Late deliveries, excess inventory, stockouts, rising costs, and unhappy customers become common. For example, a single delayed message or outdated spreadsheet can trigger a chain reaction across operations.

Because of this, speed and accuracy are essential in 2026. That’s why strong coordination is the key to delivering both.

The Biggest Logistics Challenges Facing 2026

Global Uncertainty and Market Volatility

Today’s supply chains operate in an unpredictable world. Geopolitical tensions, climate events, and changing trade rules make planning more complex. As a result, coordination allows companies to adapt calmly instead of reacting in panic.

Rising Transportation Costs

At the same time, fuel prices, labor shortages, and limited capacity continue to squeeze margins. Without proper coordination, these costs can quickly spiral out of control.

Technology Gaps and Data Silos

Despite digital progress, many businesses still rely on disconnected systems. When data does not flow smoothly, decisions slow down and mistakes increase.

1 – Centralize Communication Across the Supply Chain

The Cost of Fragmented Communication

Scattered emails, phone calls, spreadsheets, and chat tools often create confusion. As a result, teams work with different information and make poor decisions. Centralized communication solves this by giving everyone the same view at the same time.

Tools That Improve Real-Time Collaboration

Modern TMS, ERP systems, and shared dashboards allow teams to manage shipments, delays, and changes instantly. In many cases, having one source of truth can save thousands of dollars each day.

2 – Use Real-Time Data for Faster Decisions

From Reactive to Predictive Logistics

In 2026, reacting after a problem appears is already too late. Instead, real-time data helps logistics teams predict delays and adjust routes before customers notice any issue.

Key Metrics Every Logistics Team Must Track

On-time delivery, lead-time variability, inventory turnover, and carrier performance are now essential. Together, these metrics support better coordination and faster decisions.

3 – Build Stronger Relationships with Partners

Collaboration Over Competition

Suppliers and carriers should be treated as partners, not opponents. By sharing forecasts, constraints, and expectations, companies build trust and improve coordination.

How Trust Improves Supply Chain Resilience

When trust exists, communication becomes faster and problem-solving improves. As a result, the supply chain becomes more resilient during disruptions.

4 – Automate Repetitive Coordination Tasks

Where Automation Delivers Immediate Wins

Tasks such as order confirmations, shipment tracking, invoice matching, and status updates are ideal for automation. This reduces manual errors and saves time.

Human + Automation = Better Coordination

While automation handles routine work, humans focus on exceptions and strategy. Together, they create stronger coordination.

5 – Optimize Inventory Through Cross-Functional Alignment

Breaking the Sales–Logistics Wall

Sales teams aim for product availability, while logistics teams focus on efficiency. However, coordination aligns both goals through shared forecasts and planning.

Smarter Forecasting Through Shared Data

When demand, inventory, and transport data are connected, forecasting improves. As a result, inventory levels stabilize and waste decreases.

6 – Strengthen Last-Mile Coordination

Why the Last Mile Is the Most Fragile

The last mile is where customer experience is either won or lost. Without strong coordination, delays, returns, and negative reviews increase.

Local Coordination Strategies That Work

Working with local carriers, optimizing routes, and sharing delivery windows all improve last-mile performance. Ultimately, these actions boost customer satisfaction.

7 – Create a Coordination Playbook

Standardizing Responses to Disruptions

When disruptions occur, teams should not improvise. Instead, a coordination playbook clearly defines roles, actions, and timelines.

Training Teams for Consistency

Regular training ensures teams respond quickly and consistently. Over time, this builds confidence and efficiency.

8 – Invest in Skills, Not Just Systems

The Human Side of Logistics Coordination

Technology supports coordination, but people make it work. Therefore, communication, problem-solving, and critical thinking remain essential.

Skills That Matter Most in 2026

Data literacy, cross-functional collaboration, and adaptability are the most valuable skills. Together, they strengthen coordination across the supply chain.

9 – Leverage Digital Twins and Scenario Planning

Simulating the Supply Chain Before Problems Hit

Digital twins allow companies to test scenarios safely. For example, they can explore disruptions without real-world risk.

Turning Insights into Action

The real value lies in using these insights to improve decisions. As a result, companies act before problems escalate.

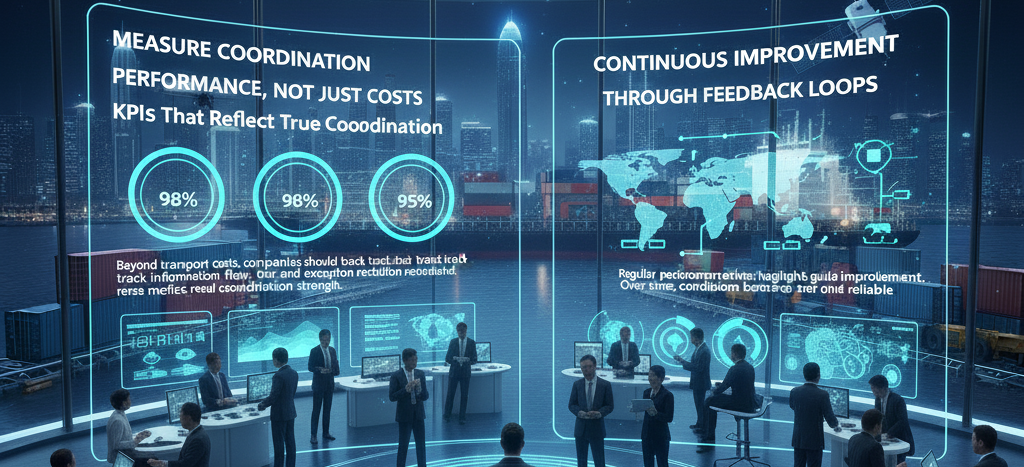

10 – Measure Coordination Performance, Not Just Costs

KPIs That Reflect True Coordination

Beyond transport costs, companies should track information flow, response time, and exception resolution. These metrics reveal coordination strength.

Continuous Improvement Through Feedback Loops

Regular performance reviews highlight gaps and guide improvement. Over time, coordination becomes stronger and more reliable.

Conclusion – Coordination Is the New Competitive Advantage

In 2026, logistics coordination is no longer a background activity. Instead, it is a strategic advantage. Companies that align people, data, and processes outperform competitors, satisfy customers, and manage uncertainty more effectively.

Simply put, coordination is the glue that holds the supply chain together. Strengthen it, and everything else works better.